singlespeed

Well-known member

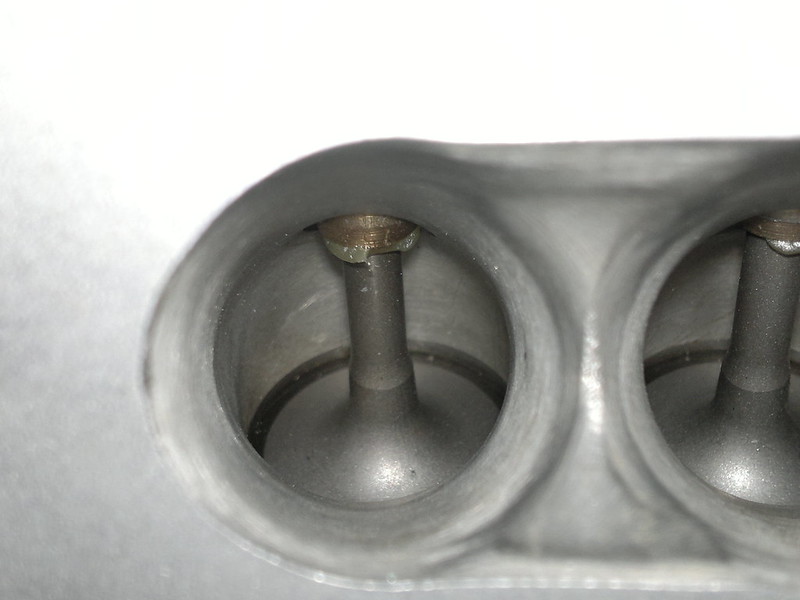

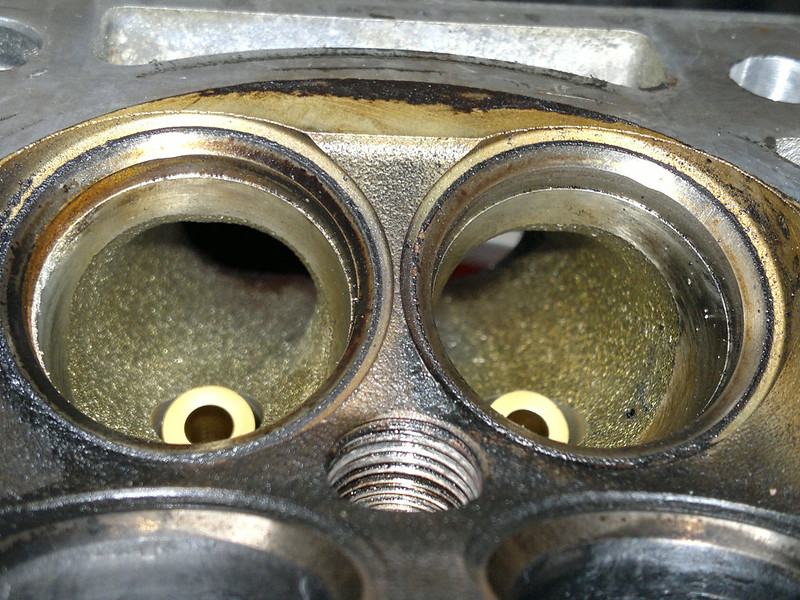

Theres probably some improvemnts to be made from profiling the inlet valve guides or making them flush. Also, the siamese divider is rather blunt.

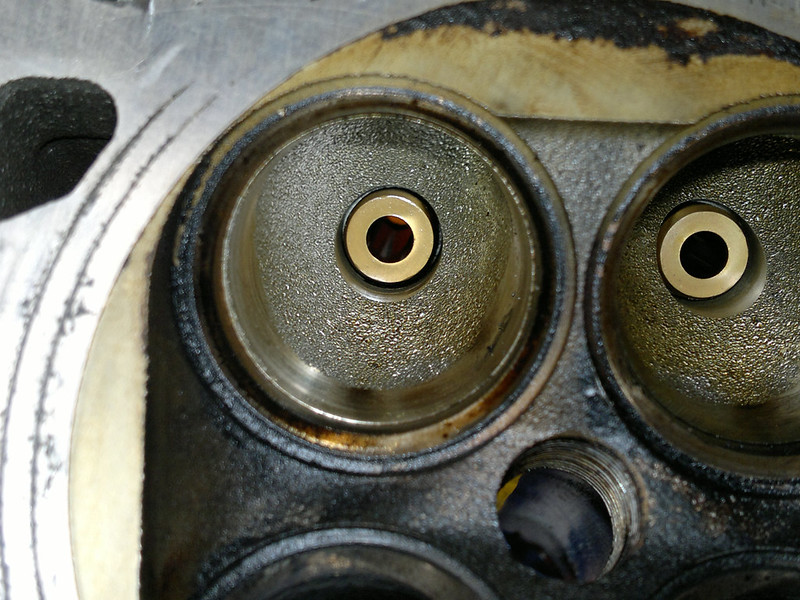

The step from casting to valve seat can be opened out and the seats cut to 30,45 and 60deg instead of the single angle cut thats there now.

The short radius between valve seat and the floor of the intake is way sharper than needs be, especialy where the valve seats have been machined into the casting

Not much room to go up a size with the valves

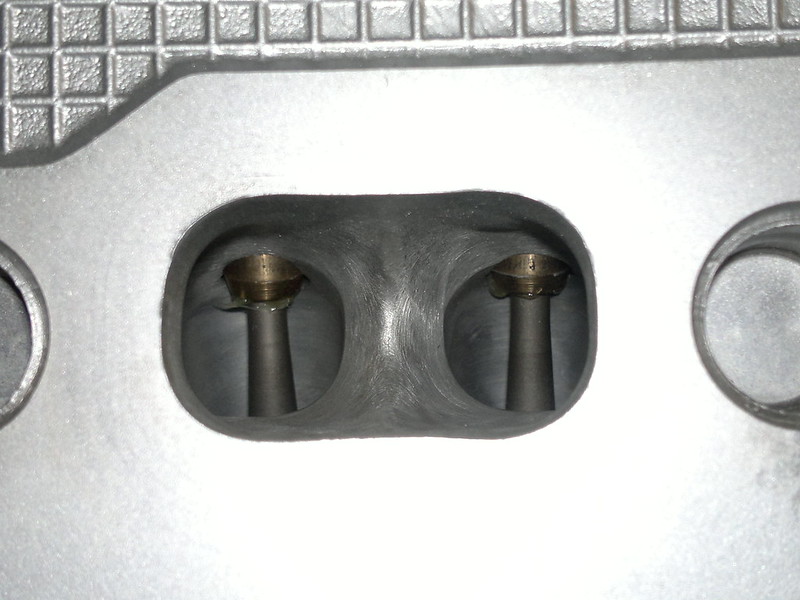

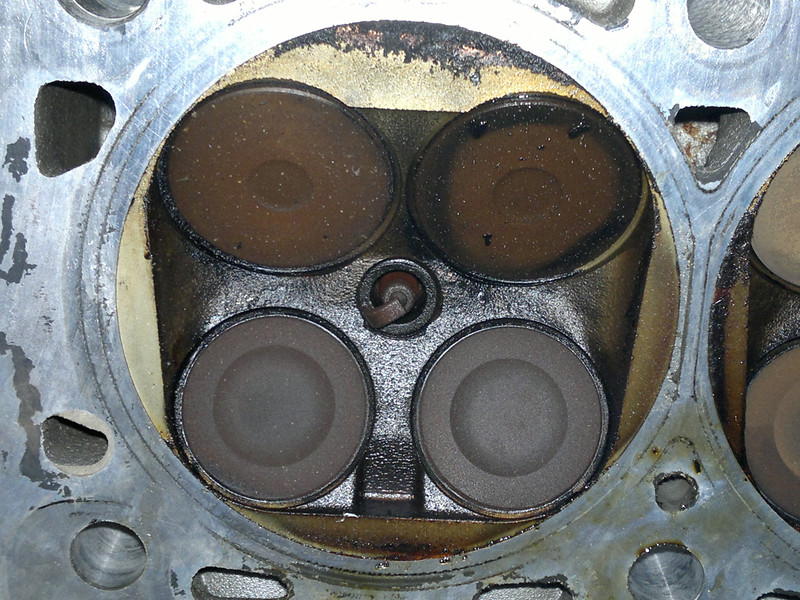

I'm sure the areas around the valves could be improved, which would give better flow at small valve lifts. Again, theres a sharp radius where the valve seat cut meets the floor of the exhaust port

Like the inlet side, the exhaust valve guides aren't that prety and the casting texture and joint marks could be easily improved.

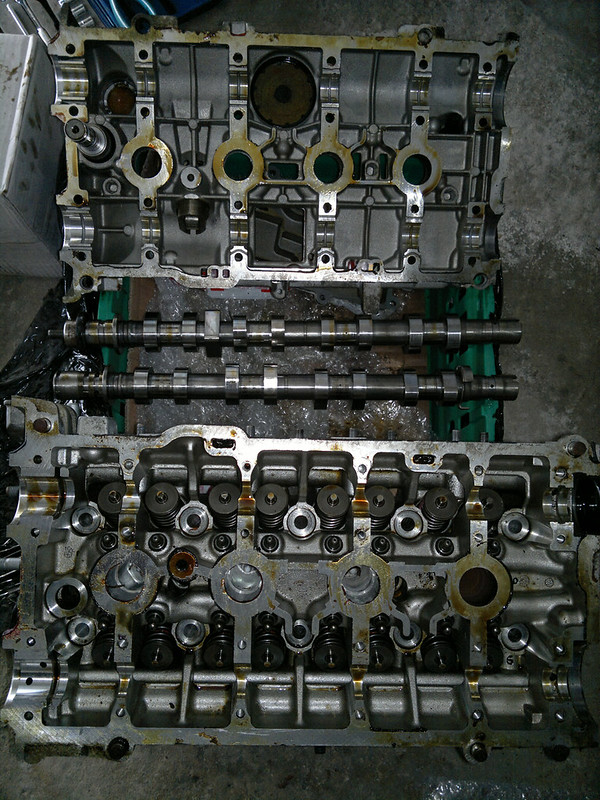

As I'm going to be getting the valve seats re-cut, I'll leave the dremmel alone this time, even though it looks rather good when compared to old fords, vauxhalls and A seies heads that I've previously had a go at. The gains aren't going to be huge and could actualy go backwards if done badly, hence getting a recomendation from Paul at RS Tuning for having the work done by the place they use. Besides one of the exhaust valves being slightly bent, it's not looking too bad... Nothing that a good wash and hitting with a die grinder and sanding wheel can't fix

Interestingly, the two spark plugs nearest the waterpump looked to be in a simillar corroded state to the ones Karl took out of his motor :?