Upper intake manifold removal

Whilst this isn’t particularly difficult, theres quite a bit of working blind to remove five bolts and a couple of hoses behind the manifold, where access is limited.

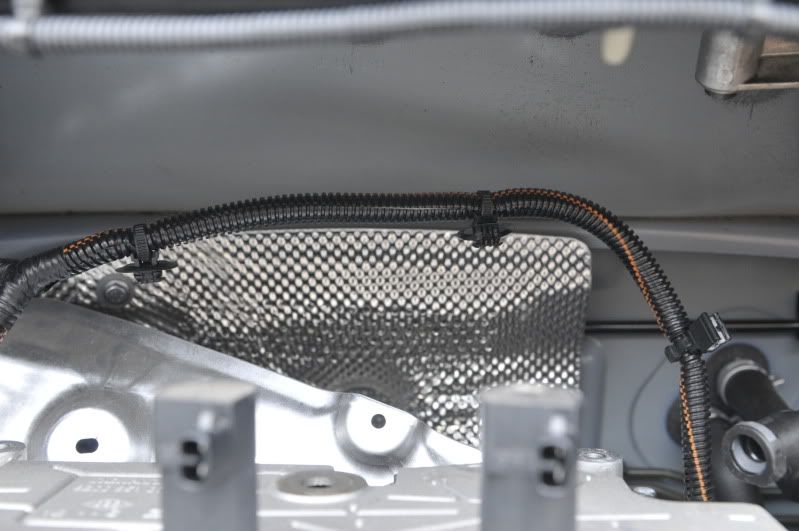

View behind the manifold, showing cable secured to the top of the manifold and breather pipe behind the heatshield

Tools required:-

7 and 8mm sockets

T20 bit

Small flat blade screwdriver

1. Remove the top of the airfilter box (T20 bit) and the inlet hose (7mm for jubilee) to the throttle body. remove the crankcase breather hose from the elbow fitting instead of trying to remove it from the rear of the manifold.

2.

Remove the cables from the front of the manifold:-

2a. remove the spark plug coil connectors bt pressing down on the tab then use a screwdriver to gently pull back

2b. Remove the wire retaining clip then pull off the connector. Here, the retaining wire is back in place.

2c. The cable retaining clips pull free with a little force or you could cut the ty-wraps, allowing the loom to be moved out of the way.

3.

Remove the throttle body:-

3a. Push against the tab with a small screwdriver to release the connector

3b. Undo the four bolts (8mm) holding the throttle body to the plenum

4.

Remove the two hoses and sensor from the rear of the manifold:-

4a. The hose on the passenger side is released by pressing down on the grey tab, then pulling the hose off.

4b. The sensor on the drivers side can be pulled free (upwards) as it is only held in by an o-ring. I disconnected it before realising, as can be seen in the pic below

4c. The hose on the drivers side is released by pressing in against on the black tab, then pulling the hose off.

4d. Either cut the three ty-wraps or pull the securing tabs free to release the loom from the manifold

5. Remove the three horizontal bolts (8mm) securing the heatshield to the back of the manifold

6. Remove the two vertical bolts (8mm) securing the back of the manifold to the cam cover.

7. Remove the remaining six bolts (8mm) that are visible

8. Lift the manifold free from the locating spigots at the front, then remove out from the passenger side, paying attention to not damage the breather seal on the underside of the plenum.

Throttle body and manifold clean up

Theres was a lip, shown here on either side of the butterfly.

After some work with the Dremel and sanding drum, followed by some 500 grit paper to remove the lip and also match the TB to the plenum inlet

The casting of the manifold is quite good quality, only requiring minor fettling to remove any prominent lumps and bumps. There is probably room for improvement where the upper and lower inlets meet but this would take a while to do, besides needing the lower manifold off, so left for later